Published

- 3 min read

The history of Textile from the Industrial Revolution to the age of AI

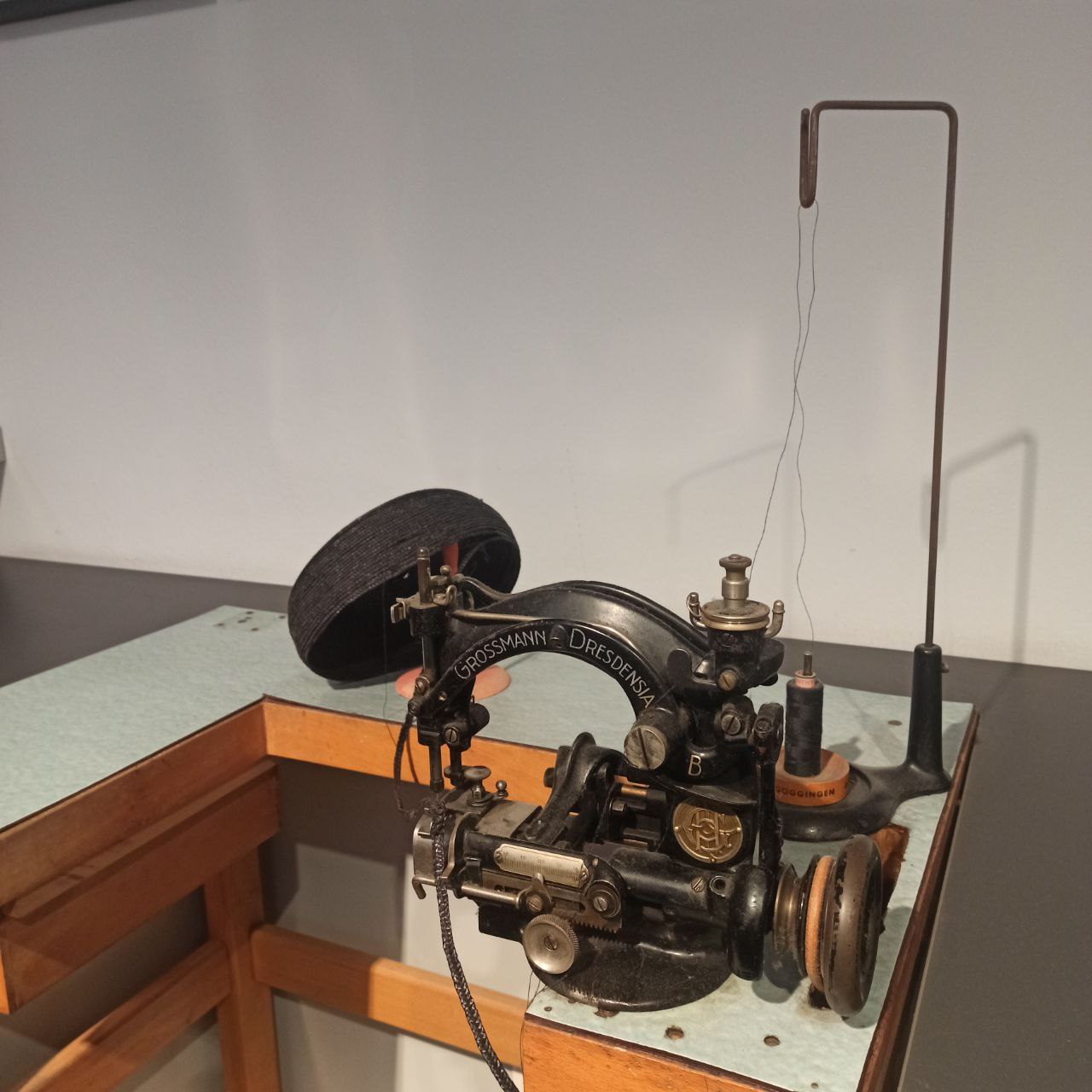

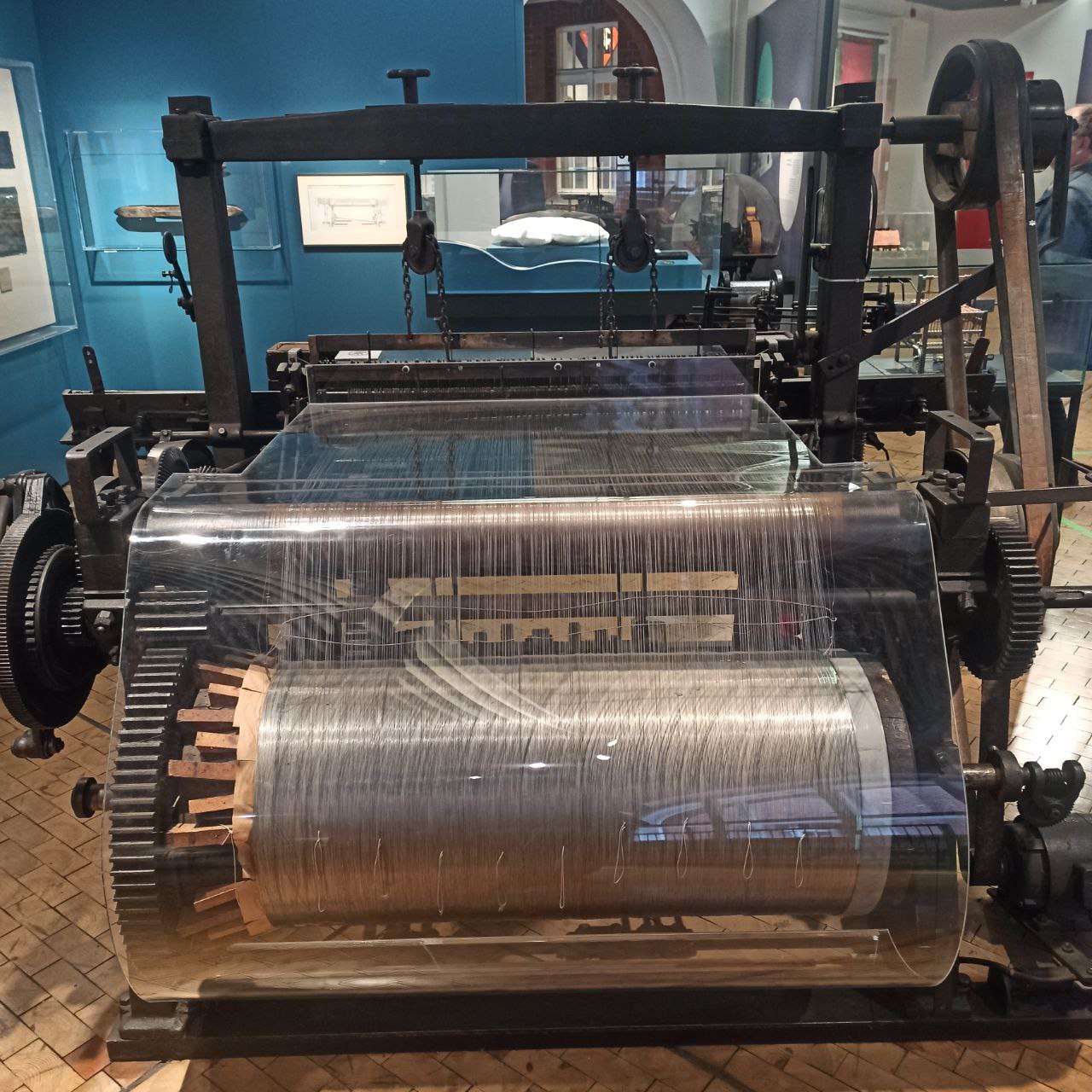

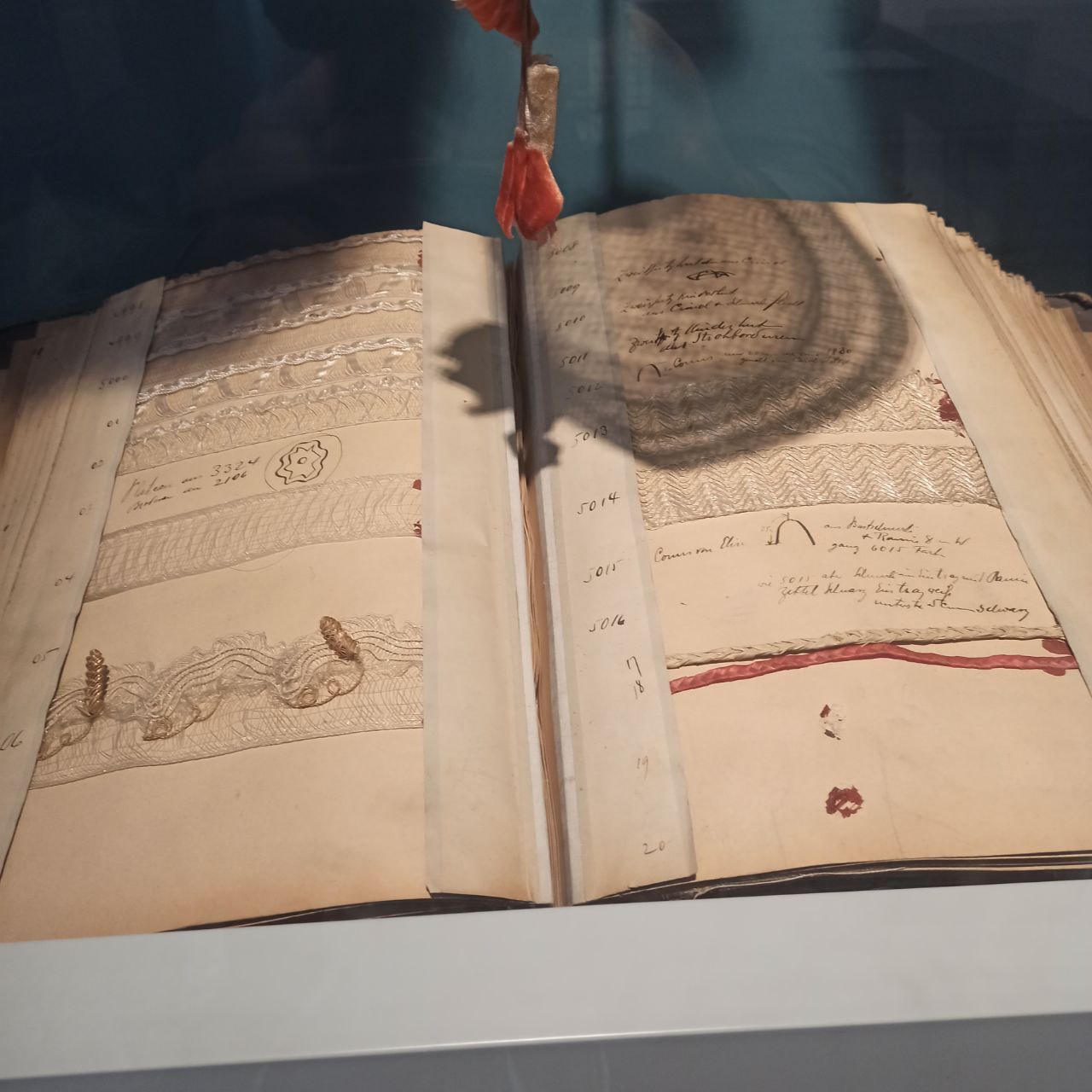

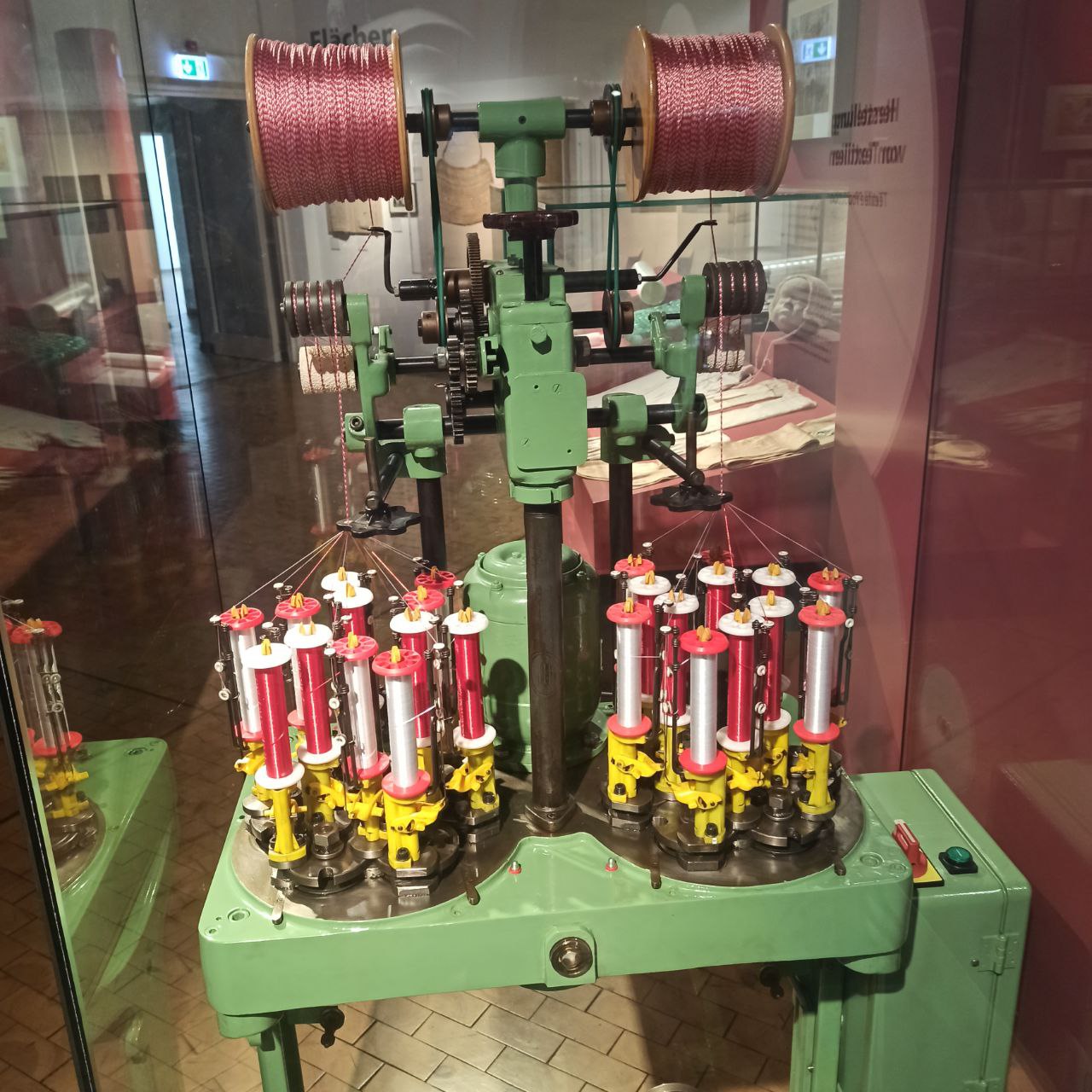

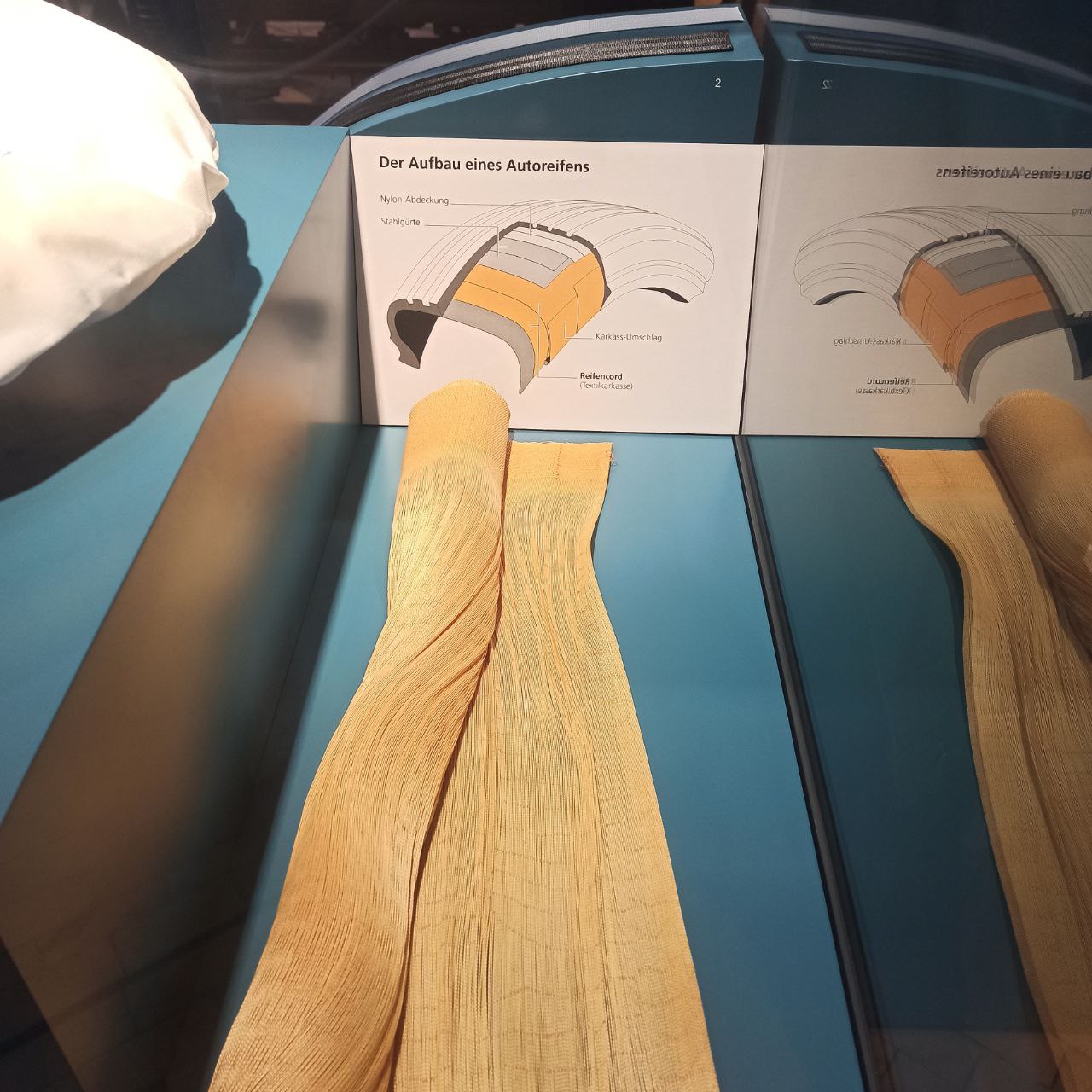

At the beginning of the industrial revolution, textiles (cotton), steel, and coal were the dynamos of the industrial revolution. Large systems (production plants) were built using coal, steel, and steam to increase cotton and textile production. There was always innovation for more production, more efficiency, minimum labor involvement, and more profit. Sewing machines, spinning machines, cotton washing, picking machines, dyeing tools, chemicals, knitting machines, and new machines are added daily.

Weaving, knitting and knotting are ancient cultural technologies. For thousands of years, people all over the world have been using these techniques to make clothing and everyday objects. Textiles can be firm or supple, sturdy or light fireproof or water-resistant. Such qualities are determined by choice Of material and production technique.

In the past, a hat was worn on the head as a symbol of rank, status, profession or political opinion. Today, hats are mainly fashionable ornaments. Hat makers in trade and industry make hats mainly from felt (for winter) or straw (for summer). Milliners have been making imaginative headgear for women since the 19th century. Hat making has lost much of its importance since the second half of the 20th century. It lives on where national or religious identity is expressed in the headgear.

In the past, a hat was worn on the head as a symbol of rank, status, profession or political opinion. Today, hats are mainly fashionable ornaments. Hat makers in trade and industry make hats mainly from felt (for winter) or straw (for summer). Milliners have been making imaginative headgear for women since the 19th century. Hat making has lost much of its importance since the second half of the 20th century. It lives on where national or religious identity is expressed in the headgear.

North America, Europe, and the United Kingdom are two states that led this industrial revolution. Today, Spanish Italian, and Japanese companies carry on this revolution.(Source : Wikipedia).

The most important textile surfaces are knitted fabrics and woven fabrics. Knitted fabrics are created by continuously interlacing loops of thread. Woven fabrics are the crossing of two thread systems. The first technique involves knitting, the second involves weaving.

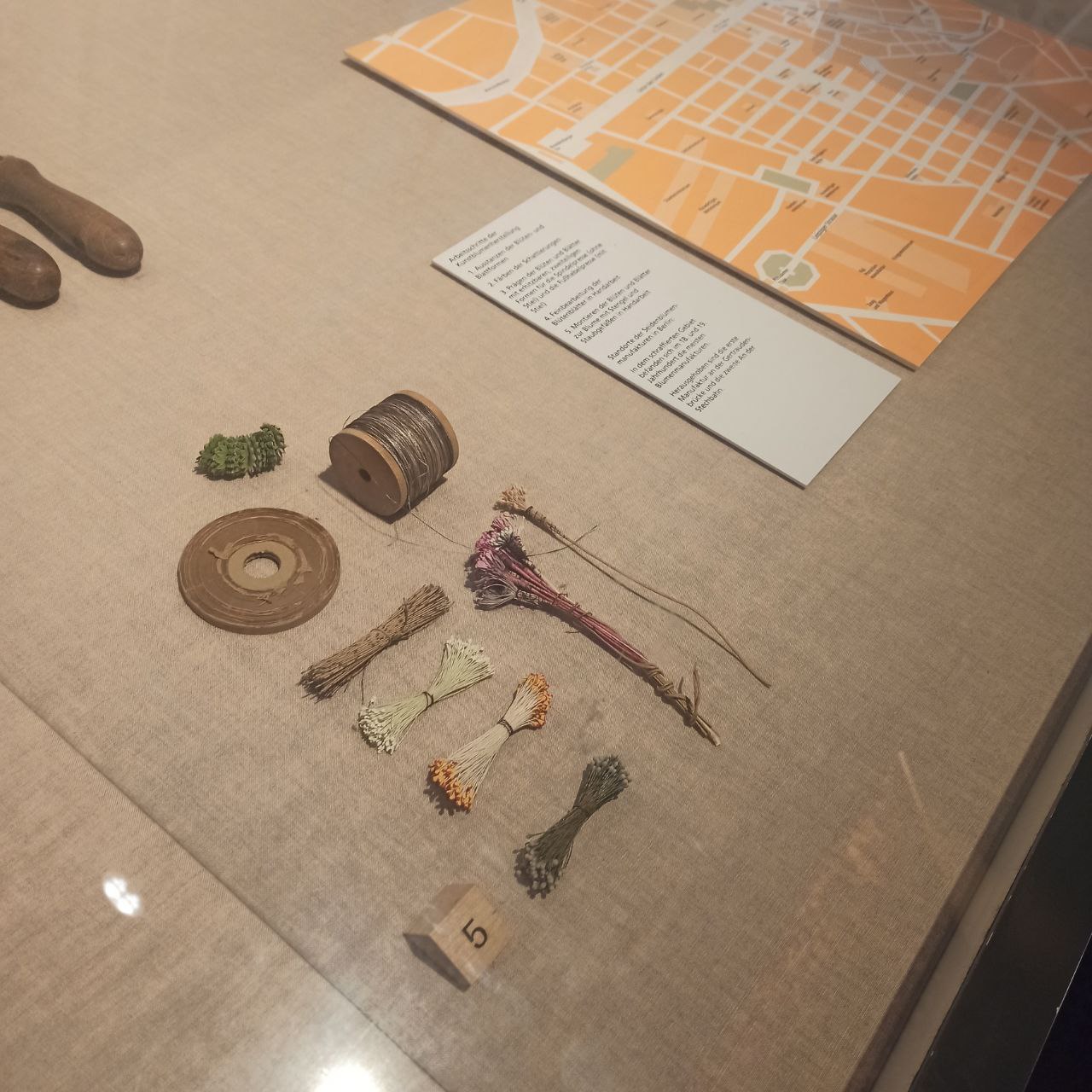

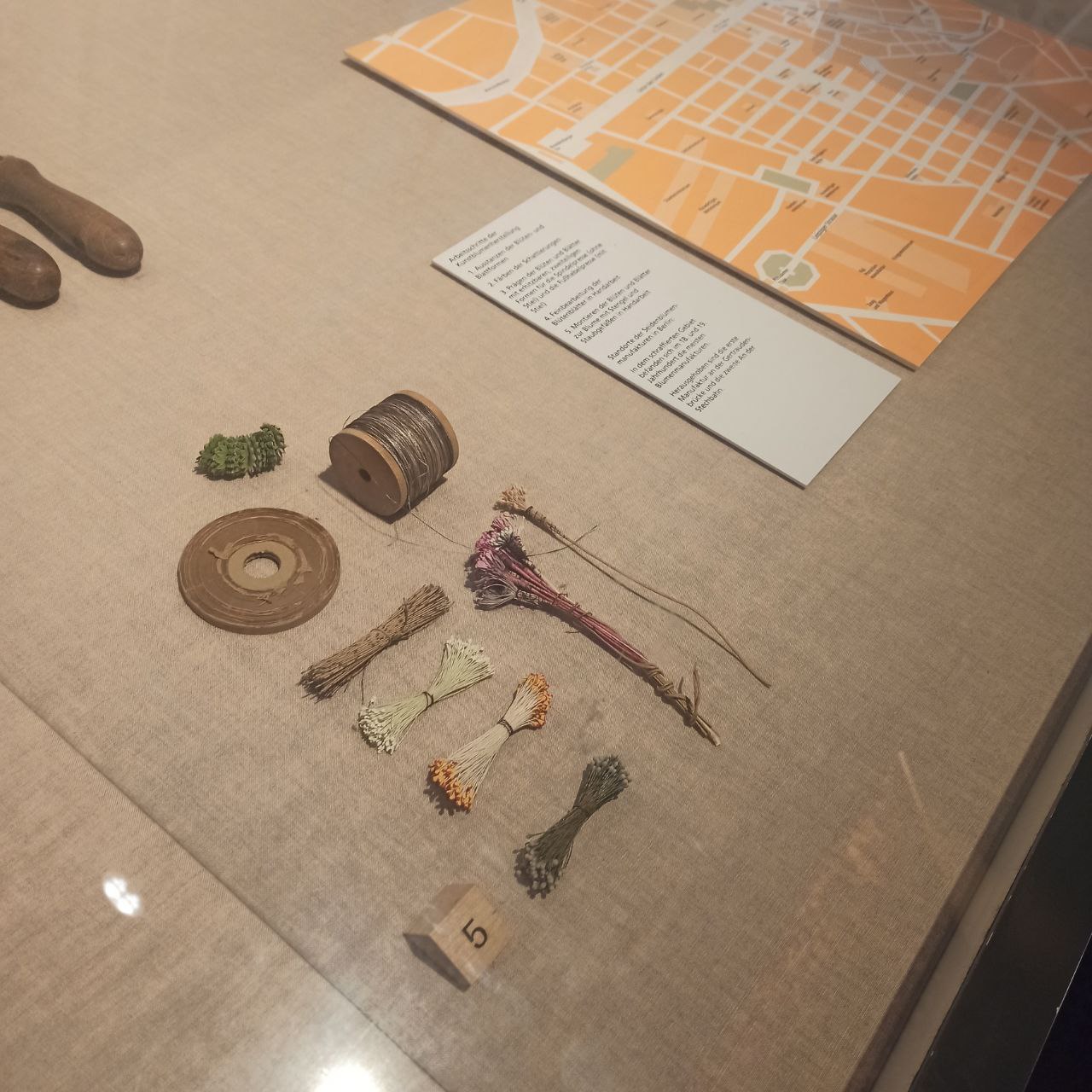

Steps in the production of artificial flowers:

- Punching out the flower and leaf shapes

- Coloring the shades

- Embossing the petals and leaves with heatable two-part molds for the spindle press (without stem) and the foot-operated press (with stem)

- Fine processing of the petals by hand

- Assembling the flowers and leaves to form the flower with stem and stamens by hand Locations of the silk flower factories in Berlin: In the 18th and 19th centuries, most flower factories were located in the hatched area. The first factory on the Gertraudenbrücke and the second on the Stechbahn are particularly notable.

The other day I visited the textile section of the Deutsche TecknikMuseum, one of these museums. I examined the machines and fabrics in this museum, which has a barely visible door on the left side of the ground floor. You can visit this museum for free on the first Sunday of every month in Berlin. The ticket price for other days is 12 Euros.

The museum in Berlin Schöneberg contains incredible artifacts. From the primitive ships at the bottom to the orbital satellites at the top, all of them were incredibly detailed and explained.

Sometimes there can be a queue at the museum, and since the museum is extremely large, I think you should go around 10 in the morning and admire the intelligence of human beings.

In the 19th century, Joseph-Marie Jacquard improved upon the loom. Weaving patterns were translated onto punch cards. These cards controlled the loom’s movement, raising and lowering the warp thread. The new technique made it easier to work a loom sped up production, and laid the foundation for the digitization of textile production.